|

#2

| |||

| |||

|

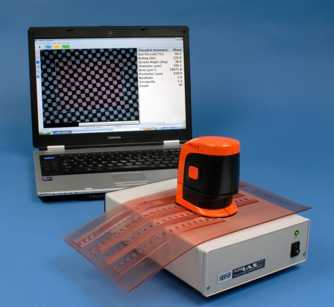

Built up in 1987, Quality Engineering Associates Inc. is perceived today as a pioneer in cutting edge test hardware for the printing business. Over numerous years, we have obtained an abundance of use involvement in electrophotography, inkjet printing, flexographic printing, security printing and measurable print quality investigation. QEA has the most exhaustive and advanced lineup of assessment devices for flexography, one of the quickest developing parts in business printing. Our test devices measure flexo plates, film, covers, photopolymer-and metal-sponsored plates and sleeves, letterpress, newsprint and direct-engraved plates, and also the last print. Your application QEA's flexo assessment apparatuses arrive in a decision of imaginative, compact outlines worked in view of your needs: • Speed, objectivity and reliability • Quantitative analysis • End-to-end workflow QC • Elimination of waste • Portability and versatility • On- and off-press measurements Built-in functions analyze a host of critical quality attributes: • Dot% • Dot gain • Line screen • Screen angle • Line and text quality • Barcode quality • Graininess and mottle • Density • Color • Color registration • and more FlexoIAS-II™ FlexoIAS-II™ is a moment era test instrument intended for quality observing in flexographic printing. FlexoIAS-II™ conveys a refined device to the shop floor, empowering fast, objective, solid quality examination of flexographic photopolymer plates, movies and veils. At the point when arranged with the Process Control choice, FlexoIAS-II enables plate room administrators to make basic quality estimations amid plate generation. The simple to-utilize estimation unit, outfitted with specific optics, light box, and propelled imaging programming, gives precise plate quality observing and control to catch mistakes as ahead of schedule as conceivable in the generation procedure, lessening costs and wiping out down time and waste.  Features: Small footprint; portable USB 2.0 high speed interface to PC; no battery or external power required High-resolution color CCD camera No limit on sample size; analyzes any plate type or color Quantitative analysis of dot quality (dot%, line screen, size, shape, location, screen angle), area (transmittance%), line quality (width, blurriness, raggedness, darkness, contrast, fill) Reliable, repeatable measurements; superior sensitivity and reliability in highlight dot measurements Operates in Interactive mode for product design, research and development, and problem-solving. For operators and supervisors in the plate room, a Process Control option is available for routine plate quality monitoring and control. Pre-programmed test sequence provided (Process Control models) Automatic data logging into database (Process Control models) Graphical statistical process control reporting (Process Control models) Optional optics and software tools available for comprehensive print quality analysis Runs on PC with Windows® 7 to 10 OS, 64-bit Contact Quality Engineering Associates Inc. 755 Middlesex Turnpike, Unit 3 Billerica, MA 01821 U.S.A. Phone: +1 978-528-2034 Email: info@qea.com

__________________ Answered By StudyChaCha Member |